Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

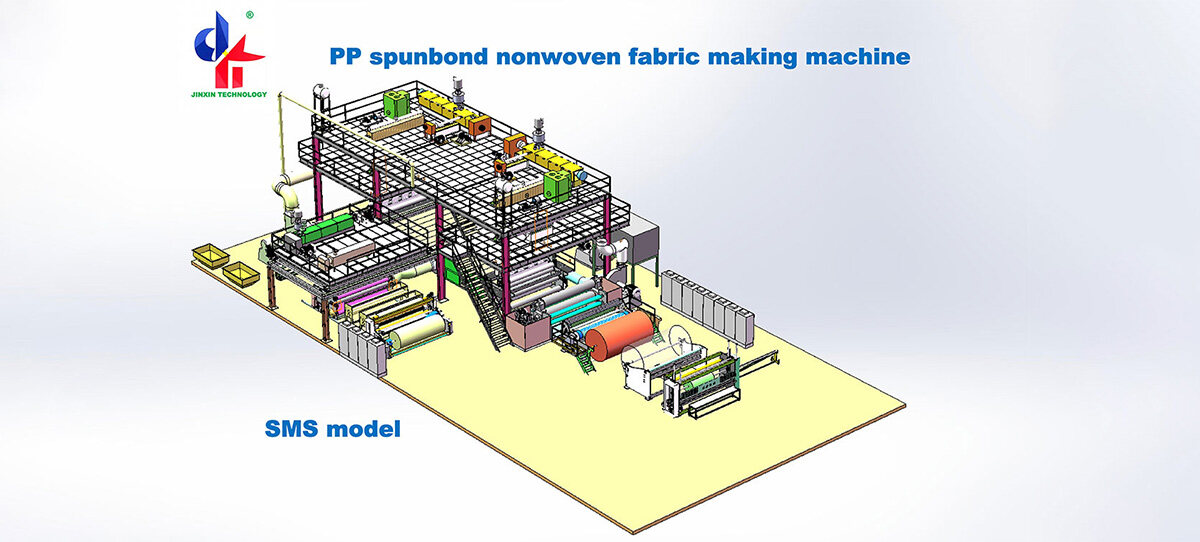

Machine à non-tissé SMS

A three-layer composite non-woven fabric made of top spunbond polypropylene, middle melt-blown polypropylene, and bottom spunbond polypropylene is known as spinning melt non-woven fabric, or SMS. It can be claimed that it combines the benefits of spunbonded non-woven fabric with meltblown cloth. SMS non-woven fabric is a staple in the medical and healthcare industries and is used to make masks, disposable protective gear, and protective garments.

| Model | JX-SMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 40*16*12m | 40*18*12m | 40*22*12m |

| Mechanical Speed | 400m/min | 400m/min | 400m/min |

| Gram Weight | 10-150g/m2 | 10-150g/m2 | 10-150g/m2 |

| Daily Output | 8-12T/Day | 12-16T/Days | 16-22T/ Day |

| Transformer Capacity | ≈800KVA | ≈1250KVA | ≈1600KVA |

| Power Consumption | 1200°-1650°Ton | 1200°-1650°Ton | 1200°-1650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Why do you need SMS non-woven fabrics?

Spinning melt non-woven fabric, commonly known as SMS, is a three-layer composite non-woven fabric, which is composed of top layer spunbond polypropylene, middle layer melt is blown polypropylene, and bottom layer spunbond polypropylene. It can be said that it is a combination of meltblown fabric and spunbonded non-woven fabric, with both advantages. SMS non-woven fabric is widely used in the medical and health field and is the key material for protective clothing, disposable protective articles, and masks.

Due to the combination of spunbond and meltblown technologies, SMS will encounter the following problems in the production process:

1.The production parameters do not match

The basis weight and performance of melt-spun nonwovens depend largely on the combination of material throughput and conveyor belt speed in the production process. However, the spunbond and melt-blown processes cannot be realized with the same factory parameters. The throughput required for the production of spun-bond layers is significantly higher than that required for the production of meltblown layers, resulting in problems in SMS production.

2.Reduced air permeability

Different non-woven fabric layers are directly produced on top of each other in the composite process, which compacts the filter layer, thus reducing the air permeability of the spun melt non-woven fabric. However, the air permeability of melt-spun nonwoven fabric is very important for the production of filters and masks.

3.Difficult post-processing

The filter material produced by melt-blown technology must have static electricity, otherwise, the smallest particles such as viruses cannot be reliably filtered. Although this post-treatment can be realized in the SMS composite process, it is much more complicated in hardware than when the filter layer is produced separately in the independent melt blown process.

How do solve the problems in the production of melt-spun non-woven fabrics? The melt spun non-woven fabric machine developed and produced by Fujian Jinxin Machinery Technology Co., Ltd. with 15 years of design experience and technical precipitation can meet the production needs, fully integrate melt blown and spunbond technologies, optimize the production process, achieve high-efficiency production, and produce melt spun non-woven fabrics that meet the needs of users and various standards. Please inquire for details.