Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

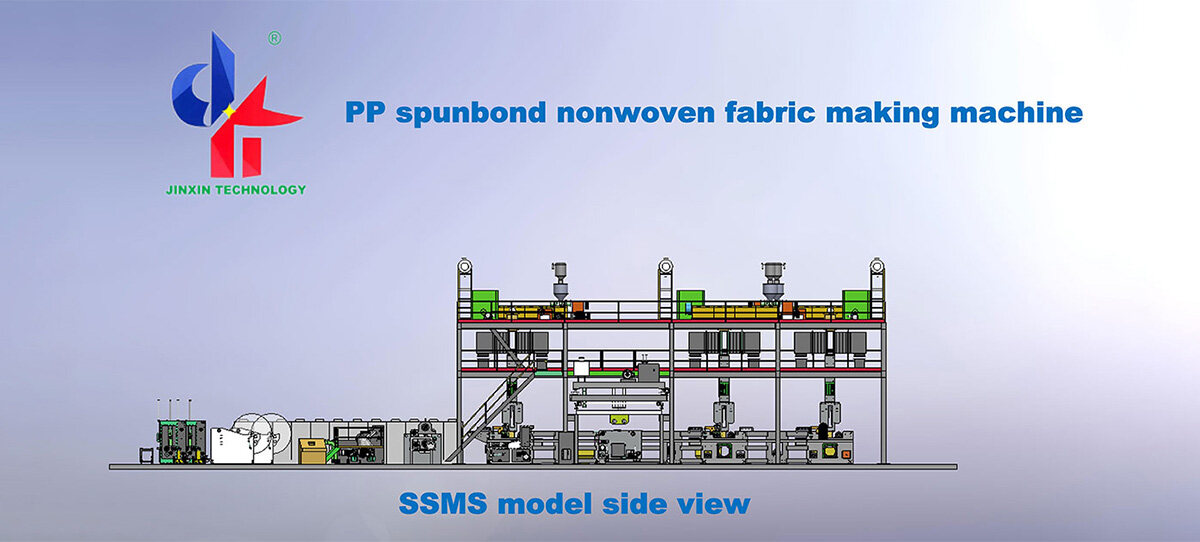

Machine non tissée SSMS

The spunbond non-woven machinery is constructed using top-notch assembly and welding technologies. It can sustain good working conditions for an extended period of time in a high-load processing environment thanks to its sturdy structure, high strength, long-lasting performance, and stable operation. The operator is not burdened by the automatic operating design, which is straightforward and convenient. Spunbond non-woven equipment can reduce labor expenses significantly and increase profits for businesses.

| Model | JX-SSMS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 50*16*12m | 50*18*12m | 50*22*12m |

| Mechanical Speed | 450m/min | 450m/min | 450m/min |

| Gram Weight | 10-120g/m2 | 10-120g/m2 | 10-120g/m2 |

| Daily Output | 10-16T/Day | 16-24T/Day | 22-30T/ Day |

| Transformer Capacity | ≈1000KVA | ≈1350KVA | ≈1800KVA |

| Power Consumption | 1200°-1650°Ton | 1200°-1650°Ton | 1200°-1650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Equipment characteristics

The spunbond non-woven equipment is built with excellent assembly and welding technology as a whole. It has a strong structure, high strength, durable performance, stable operation, and can maintain good working conditions for a long time in a high-load processing environment.

The automatic operation design is simple and convenient, and there is no burden for the operator. The use of spunbond non-woven machinery can save a lot of labor costs and achieve higher benefits for enterprises.

With stable and reliable processing quality, the overall non-woven products show uniformity, which can maintain a high degree of quality uniformity, reduce the defective rate, greatly improve the market competitiveness of anti-stick non-woven products, and bring continuous improvement to the enterprise income.

As a popular high-quality fabric, spunbond non-woven fabrics naturally need to pay attention to the quality of the process during the production process. Choosing high-quality processing equipment can significantly improve the quality of spunbond non-woven fabrics. For this, very good quality control can be achieved with our spunbond nonwoven machines.

Requirements for nonwoven machines

1.Tidiness: tools, workpieces, and accessories are placed neatly; Safety protection devices are complete; The pipeline is complete.

2.Selling: internal and external cleaning; Each sliding surface, lead screw, gear, rack, etc. shall be free of oil stain and collision; No oil leakage, no water leakage, no air leakage, and no electric leakage at all parts; Clean the chips and garbage.

3.Lubrication: fill and change the oil on time, and the oil quality meets the requirements; The oil pot, oil gun, oil cup, oil felt and oil line is clean and complete, the oil mark is bright and the oil path is smooth.

4.Safety: implement the system of fixed personnel and machine and shift handover; Be familiar with the structure of the non-woven fabric slitting machine and follow the operating procedures, reasonably use the non-woven fabric slitting machine, carefully maintain tools, and prevent accidents.