Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

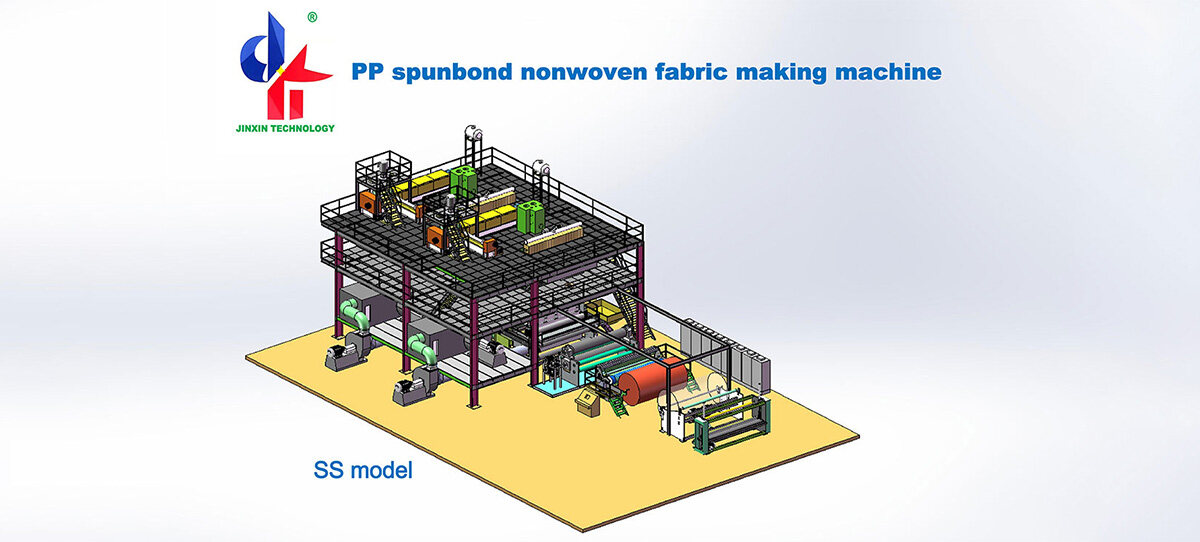

Machine de fabrication de tissu non tissé SS spunbond

A type of mechanical tool used to process spunbond nonwoven fabric, spunbond nonwoven fabric machines significantly increase the productivity of nonwoven fabric production. The spunbond nonwoven machine produces nonwoven fabric with the benefits of high strength and superior air permeability. The spunbond nonwoven machine's specific parts and work flow are listed below.

| Model | JX-SS | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 30*12*12m | 30*14*12m | 30*16*12m |

| Mechanical Speed | 300m/min | 300m/min | 300m/min |

| Gram Weight | 10-200g/m2 | 10-200g/m2 | 10-200g/m2 |

| Daily Output | 7-12T/Day | 12-15T/Day | 14-20T/Day |

| Transformer Capacity | ≈400KVA | ≈500KVA | ≈600KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

The Components And Process Flow Of Spunbond NonWoven Machine

Spunbond nonwoven fabric machine is a kind of mechanical equipment used in the processing of spunbond nonwoven fabric, which effectively improves the efficiency of nonwoven fabric production. The nonwoven fabric produced by the spunbond nonwoven machine has the advantages of high strength and good air permeability. The following are the specific components and process flow of the spunbond nonwoven machine.

Component

Transmission system

The first is the transmission system of the spunbond nonwoven production line. The transmission system includes two aspects, the internal transmission shaft and related parts, and the external transmission belt. The external transmission belt is mainly composed of a feeding device, a transmission device, and a storage device. Each device corresponds to a different process of spunbond nonwoven fabric production. The entire machine is driven by the huge internal drive shaft, and then it can achieve a very high-precision material transmission processing effect.

Control system

As the name implies, the control system is a system that controls the operation of the entire spunbond nonwoven production line. The reducer inside the spunbond nonwoven production line converts electrical signals into mechanical actions and then supports the operation of the entire mechanical transmission components of the spunbond nonwoven production line. At the same time, the spunbond nonwoven fabric production line also has the conversion function of multiple control modes, for example, it can be adjusted between automatic, semi-automatic, and manual, to meet the operation requirements of the spunbond nonwoven fabric production line under different production requirements.

The above two components form an integral spunbond nonwoven fabric production line, which provides a powerful and reliable hardware guarantee for the production of spunbond nonwoven fabrics.

Basic process

Loading(nonwoven rolls)- folding - sonic bonding - cutting, bag making(punching) - waste recycling - counting - stacking.

To further realize the effect of energy-saving and green, it has the function of reclaiming the remaining material in the production process, which automatically collects the waste leftover from the bag making during the production process, which is helpful for secondary utilization, reduces labor intensity, increases work efficiency, and also in line with the concept of environmental protection, it can also save corresponding costs. Spunbond nonwoven machine will continue to increase machine width, increase single machine speed and production capacity, pay attention to equipment processing accuracy and select new materials, improve the level of mechatronics, and further apply computer online inspection and control and network systems to ensure high productivity and high-quality products.

To ensure the quality of the final spunbond nonwoven fabric, it is necessary to ensure that all links of the spunbond nonwoven machine operation are correct and efficient. If you want to know more about spunbond non woven machinery after reading the above, you can contact us for more detailed solutions.