Erreur de format d'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

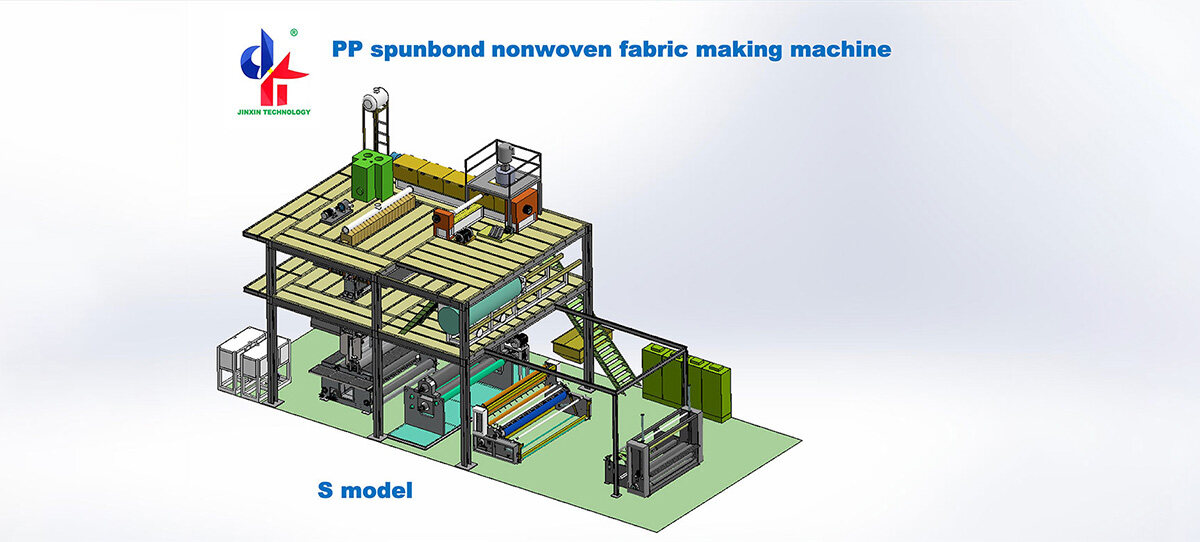

Ligne de production de machines non tissées S

The production process for spunbond nonwoven has a lot of crucial components. After use, these components must be positioned and then put back, and the instrument must be zeroed. The spun-bond non-woven fabric production line should not have combustible or explosive items stacked around it, and unnecessary knickknacks shouldn't be put on the line's table. The table must be kept spotless, and any rust or oil stains must be removed with a damp cloth.

| Model | JX-S | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 20*10*12m | 20*10*12m | 20*12*12m |

| Mechanical Speed | 150m/min | 150m/min | 150m/min |

| Gram Weight | 10-200g/m2 | 10-200g/m2 | 10-200g/m2 |

| Daily Output | 4-6T/Day | 7-8T/Day | 9-10T/Day |

| Transformer Capacity | ≈200KVA | ≈250KVA | ≈315KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Operation and maintenance requirements of S spunbond nonwoven production line

(1)There are many important parts on the spunbond nonwoven production line. These parts need to be placed and returned after use, and the instrument needs to be zeroed. Inflammable and explosive materials shall not be stacked around the spun-bond non-woven fabric production line, and irrelevant sundries shall not be placed on the table of the spunbond non-woven fabric production line. The table shall be kept clean, and some oil and rust stains shall be wiped clean.

(2)The mechanical components inside the spunbond nonwoven production line are not as good as bearings and gears, etc., which need to be carefully inspected during operation and maintenance to ensure that these parts can operate normally. For some parts that are easy to wear and tear and have failed, they shall be replaced mechanically in time. The motors, gearboxes, synchronous wheels, etc. of the spunbond nonwoven production line should be maintained at a deep level, and the circuits and mechanical mechanisms inside should be cleaned and adjusted.

(3)Sometimes there are many faults in the spunbond nonwoven production line. Some faults, such as abnormal noise and track jamming, can be eliminated by manual operation. For some parts with frequent internal transmission, some lubricating oil can be added to ensure the smooth operation of the machine.

FAQ

Q1: What’s your warranty policy?

A1: The Seller will guarantee the machine for 18 months from the date of shipment(that is leaving from the Seller’s factory) or the seller will guarantee the machine for 12 months from the date of starting installation and adjustment, whichever comes first.

Q2: What’s your minimum order quantity?

A2: Min order quantity:1 set or by negotiating with each other.

Q3: What package do you use for the product?

A3: Be Coated with anti-corrosion oil, covered with plastic film, then packed in a wooden box.

Q4: Do you have technical instructions if I buy your product?

A4: Please read the user manual carefully for your reference, we have detailed instructions on it. If your problems still can not be solved, welcome to contact us for help.

Q5: What is your overseas service?

A5: We will provide high-quality overseas service, and our technical staff will be able to provide you with technical support, for your overseas assembly and test equipment.

Q6: Will you conduct training for our staff here?

A6: Yes, we will provide technical support to factory technology, and training for the relative person.

Q7: What are your terms of payment?

A7: We accept T/T, L/C.